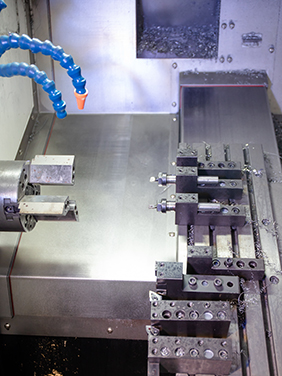

It has various fully automatic high-precision machining equipment such as Japanese Frank precision lathes, 4-axis and 5-axis machining groups, automatic CNC lathes, etc. It has high production efficiency and strong supply capacity. Free samples can be produced in 2 days and shipped in as fast as 5 days. Can meet the processing needs of different customers.

inquiry

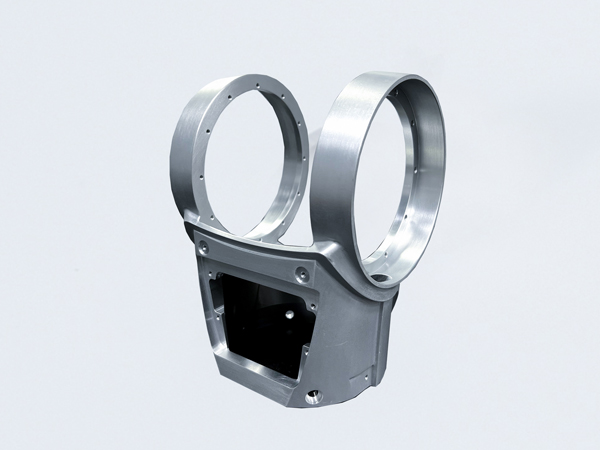

The founder has been deeply involved in the industry for more than 20 years, and the 6-person technical research team has more than 6 years of industry experience. They are good at product structure and mold equipment. They can collaborate with customers to develop and design, help customers deeply optimize the design, and make spare parts of better quality.

inquiry

It has a complete set of testing equipment such as contour measuring instrument, three-dimensional, two-dimensional, hardness tester, infrared automatic detection machine, roughness, etc. From material selection to delivery, every link is strictly monitored, and each batch of products undergoes three precision tests. , ensure that the product is qualified before leaving the factory.

inquiry

Pre-sales: Provide engineers with free on-site technical consulting services, who can collaborate with customers on R&D and design, deeply optimize drawings, and provide free proofing services;

After-sales: We will adhere to the principle of strict confidentiality for customers' design plans, and promise that we can provide redo and replacement services if customers operate due to our reasons.

36 CNC machining centers imported from Japan

36 CNC machining centers imported from Japan36 Japanese Frank CNC machining centers and automated processing production lines, with high precision and fast production efficiency

Collaborative customer development and design

Collaborative customer development and design Industry veteran engineers with 20 years of experience lead a technical research team with more than 6 years of experience, strictly review drawings, and assist customers in deeply optimizing product designs.

10 years of European and American quality

10 years of European and American qualitythe products processed are in compliance with foreign export standards such as American standards, Japanese standards, German standards, and winning standards, and have long service life.

Multiple testing procedures

Multiple testing proceduresMultiple testing equipment such as contour measuring instrument, three-dimensional, two-dimensional, hardness tester, infrared automatic inspection machine, etc. ensure that the products are qualified before leaving the factory.