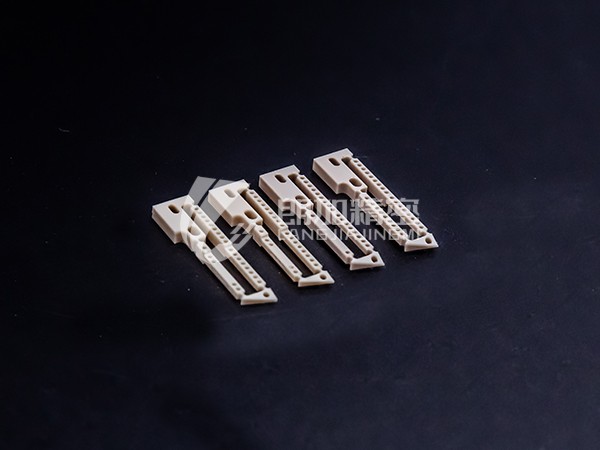

Polyetheretherketone (PEEK) can be used to manufacture suitable parts through injection molding or machining. Its melting point (343°C) can achieve faster feeding and speed. When manufacturing peek parts in large quantities, models can be made by hand-made proofing. PEEK processing is usually carried out using precision CNC machines, which can ensure that the tolerance of the produced parts is within a certain range.

whatsapp: +8613823552231

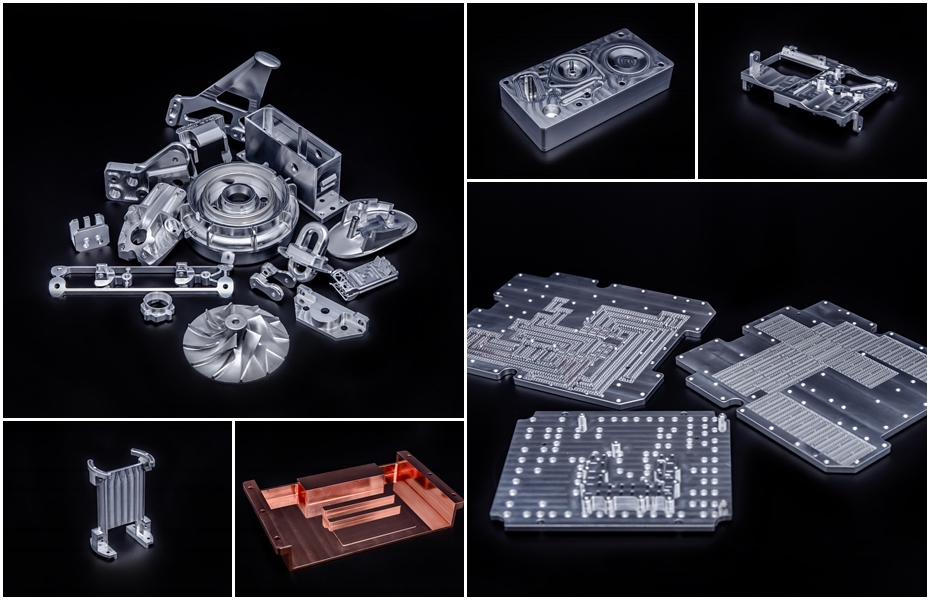

As a high-precision parts CNC processing service provider with more than 20 years of industry experience, we have been focusing on providing design and processing services for manufacturers of auto parts, electronic casings, pneumatic parts, etc. We have more than 30 Japanese FANUC machining centers, high-precision 4-axis and 5-axis machining groups, and multiple automatic CNC lathe equipment, which can provide high-precision finished products for all parts processing projects. In addition to having high-precision processing and testing equipment, we also have a skilled R&D team with 6+ years of experience studying technology to deeply optimize product design for customers. Over the years, we have taken details as our concept, craftsmanship as our core, and integrity as our foundation, and have won unanimous praise from our customers. Choose to trust us, the quality you need will exceed your expectations!

Processing accuracy

Industry experience

Japanese CNC

production plant

Processing typeCNC high precision machining |

Processing factoryGreatech |

Processing accuracyAccuracy+¬_0.005 |

|||

surface roughnessThe roughness of the processed surface can reach Ra1.6 |

Processing cycleShipping starts in three days |

Proofing cycleSamples can be produced as quickly as the same day |

|||

Processing materialsAluminum alloy, copper alloy, zinc alloy, acrylic, PEEK, ABS, etc. |

Processing applicationsAuto parts, electronic casings, molds, automation equipment accessories, medical equipment, etc. |

||||

More than 30 Japanese FANUC CNC machining centers and fully automated machining production lines.

Selected high-quality raw materials such as aluminum alloy, copper alloy, zinc alloy, acrylic, PEEK, ABS, etc.

With 20 years of experience as a master craftsman and 6+years of research and development team, we can manufacture exquisite appearance and high-precision interior products according to customer needs.

Multiple processing methods are combined to complete complex part structure processing, creating high-quality prototypes for customers' excellent products.

We have over 30 Japanese FANUC CNC machining centers, which can solve the problems of variable varieties, complex shapes, and high precision of small and medium-sized spare parts, and achieve efficient and high-precision automated machining.

We have several automatic CNC lathe processing equipment that can process simple structures such as square and circular parts.

We can cooperate with customers to perform surface treatments such as oxidation and electroplating on CNC machined parts, ensuring product quality and enhancing the added value of customers' products.

The high-precision 4-axis 5-axis machining group can complete all mechanical machining processes of spare parts in one clamping, meeting all machining requirements from rough machining to precision machining.

We have various fully automatic high-precision machining equipment such as Japanese Frank precision lathes, 4-axis 5-axis machining groups, and automatic CNC lathes. With high production efficiency and strong supply capacity, we can provide free samples within 2 days and ship as fast as 5 days, which can meet the processing needs of different customers.

The founder has been deeply involved in the industry for over 20 years, with a team of 6 skilled researchers with over 6 years of industry experience. They specialize in product structure and mold equipment, and can collaborate with customers to develop and design products, helping them optimize their designs and improve the quality of spare parts.

It has a full set of testing equipment, such as contour measuring instrument, three-dimensional, anime, hardness tester, infrared automatic detector, roughness, etc. From material selection to delivery, each link is closely monitored, and each batch of products has undergone three precision tests to ensure that the products are qualified before delivery.

Pre sales: Provide engineers with free on-site technical consulting services, collaborate with customers to develop and design, deeply optimize drawings, and provide free sampling services; After sales: We strictly adhere to the principle of confidentiality for the customer's design proposal and promise to provide rework and replacement services if the customer operates due to our own reasons.

CNC machining of robot parts refers to the process of using computer numerical control technology to accurately process various components and parts of robots. With the rapid development of industrial automation and robotics technology, CNC machining plays an important role in the manufacture of robots, and can meet multiple requirements such as high precision, complex shapes, durability and consistency of parts.

CNC lathe processing precision aluminum parts refers to the use of CNC lathes to process aluminum materials with high precision. This processing method is widely used in the fields of automobiles, aviation, electronics and mechanical engineering, and is favored because of its light weight, strong corrosion resistance and excellent processing performance.

The core of CNC machining of precision copper parts lies in the precise control of machine tool movement by the computer numerical control system. The system automatically controls the machine tool’s feed speed, cutting depth, spindle speed and other parameters by reading the pre-programmed machining program, thus achieving precise cutting, drilling, milling, tapping and other machining operations on copper materials.

CNC machining of plastic parts is a way of precision machining plastic materials through computer numerical control (CNC) technology. Compared with metal machining, CNC machining of plastic parts usually involves different material properties and processing techniques, but it can still achieve high-precision and complex shape molding.