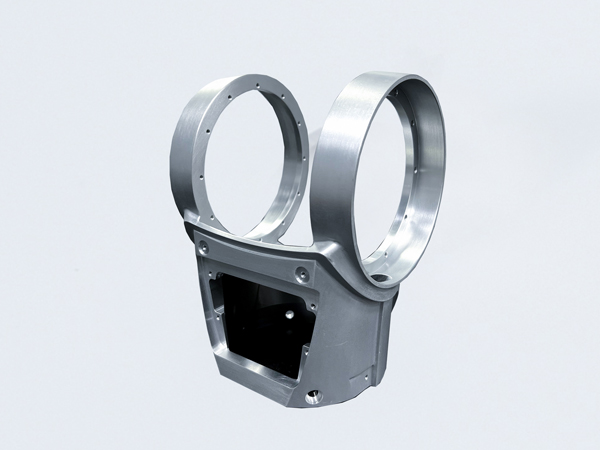

With more than 30 Japanese FANUC CNC machining centers, it can solve the problems of small and medium batch spare parts with varied varieties, complex shapes and high precision, and realize efficient and high-precision automated processing.

It has several automatic CNC lathe processing equipment, which can process parts with simple structures such as square and round shapes.

We can cooperate with customers to carry out surface treatments such as oxidation and electroplating on CNC machining parts to ensure product quality and enhance the added value of customer products.

The high-precision 4-axis and 5-axis machining group can complete all machining processes of parts in one clamping, meeting all machining requirements from rough machining to fine machining.

Quote

Design

Materials

Sample

Contract

Batch

Surface

Detection

Shipping

As a high-precision CNC machining service provider with over 20 years of industry experience, Langjia Precision has been dedicated to providing design and machining services for manufacturers of automotive parts, electronic casings, pneumatic components, and more. We have over 30 Japanese FANUC machining centers, high-precision 4-axis 5-axis machining groups, and multiple automatic CNC lathe equipment, which can provide high-precision finished products for all parts processing projects. In addition to having high-precision processing and testing equipment, we also have a 6+year skilled R&D team dedicated to researching technology, which can deeply optimize product design for customers.

| Processing Type | High-speed CNC machining, CNC lathe machining, post-processing | Processing Factory | Greatech |

| Processing accuracy | Accuracy ±0.005 | Processing materials | Aluminum alloy, copper alloy, zinc alloy, acrylic, PEEK, ABS, etc. |

| Surface roughness | The surface roughness can reach Ra1.6 | Processing cycle | Delivery within 3 days |

| Proofing cycle | Samples can be completed on the same day | Processing Application | Auto parts, electronic housings, molds, automation equipment parts, medical equipment, etc. |